Automotive

SMOOTH SOLUTIONS FOR YOUR LATEST SLEEK DESIGNS

Create the best starts and even better finishes

The competition for creating quality, cutting-edge design in vehicles is hotter than ever. We understand that precision and cost effectiveness are key drivers for the automotive industry, while protecting the quality and experience for your buyers.

Deburring is a crucial process to remove any sharp edges and burrs that remain on the surface, or edges, of metal parts after machining. These burrs can negatively impact part assembly, increase wear, and even compromise safety.

Deburring is therefore essential for enhancing the performance, longevity, and overall quality of critical vehicle components such as transmission gears, brake calipers and fuel injector nozzles.

In the automotive industry, where parts often operate under high stress and at high speeds, deburring ensures that parts meet today’s strict quality standards and operate as needed.

Given the critical nature of component precision, deburring has become a standard and non-negotiable step in the automotive production process.

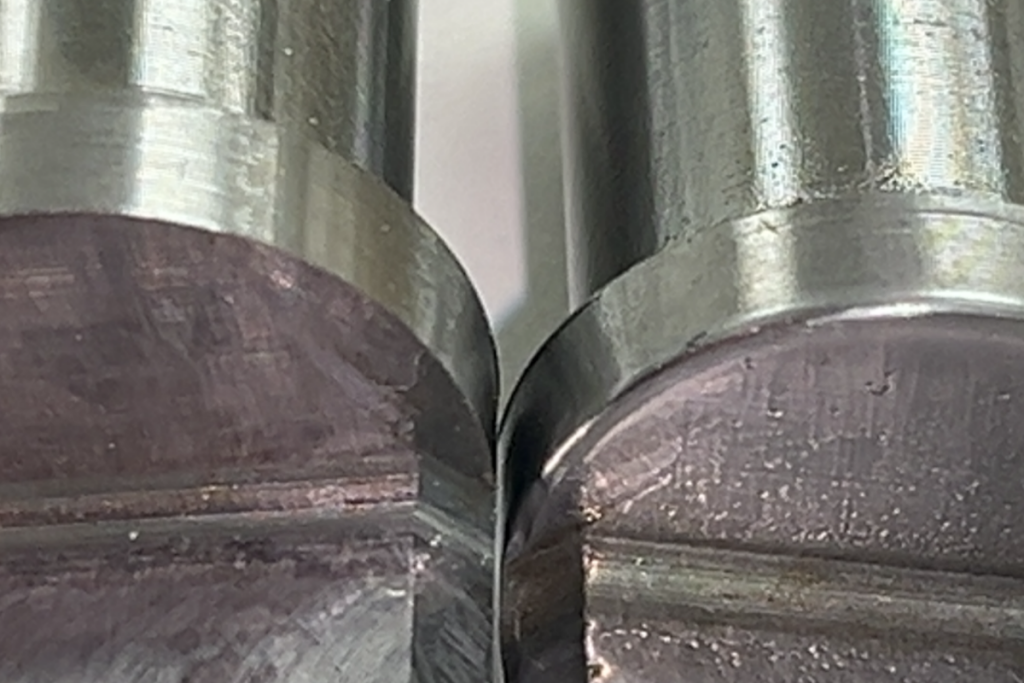

We provide specialist solutions for deburring of highly stressed components for off highway, heavy transport gear trains and engine components, particularly when a controlled, defined edge shape is required. We can selectively process components with precision, control and repeatability, ensuring consistent burr removal and smooth edges on critical vehicle parts.

AUTOMOTIVE APPLICATIONS

EDGE SHAPING

Create precision edge shapes in your critical parts – deburr and edge break gears, or create natural and smooth radius on decorative parts.

SURFACE PREPARATION

Create reliable bonding surfaces for any metal components.

PART MARKING

Create robust QR and similar barcodes on complex and curved surfaces automatically.

Start your Automotive project with us today

Have a question or need more information?

Get in touch with us today – we’re here to help!