Medical

Clean, Precise Manufacturing Solutions for the Medical Industry

Engineered to the highest standards for healthcare

From implants to surgical instruments, our technology supports the medical industry with cleaner, more precise and scalable manufacturing solutions.

The medical sector demands the highest standards of precision, cleanliness, and reliability. Our electrochemical jet machining process has been developed to meet these exacting requirements, offering a non-contaminating solution that avoids the use of undesirable chemicals. Any electrolyte residues can be easily removed with water, ensuring components remain biocompatible and ready for clinical use.

With the ability to selectively machine implants and devices in a highly controlled manner, we eliminate the need for cathode tooling or masking, reducing both process time and manufacturing complexity. This level of precision not only ensures consistent quality but also enables design flexibility for increasingly intricate and customised medical components.

Compared to laser-based methods, our process avoids the heat-affected zones that can introduce stress and reduce fatigue life in critical parts. By machining without heat, we maintain the integrity and long-term performance of medical implants and instruments. In addition, where lasers require a direct line of sight and struggle to achieve variable depths, our technology allows fine control over depth and definition — enhancing the durability and controlling the mechanical impact of part markings. This flexibility also opens up new possibilities for marking locations that would be challenging with traditional laser techniques.

Our technology is ideally suited to the materials commonly used in medical applications, such as titanium, stainless steel, and cobalt alloys. These difficult-to-process substrates can be treated efficiently and with minimal risk of damage, delivering the clean edges and surfaces that are essential for safe and durable implants.

As the industry continues to move towards patient-specific solutions and advanced manufacturing methods, our process provides a future-proofed platform that can adapt to new designs and materials. Whether supporting the development of next-generation implants or improving the efficiency of established medical device production, TextureJet offers a cleaner, more precise, and scalable alternative.

MEDICAL APPLICATIONS

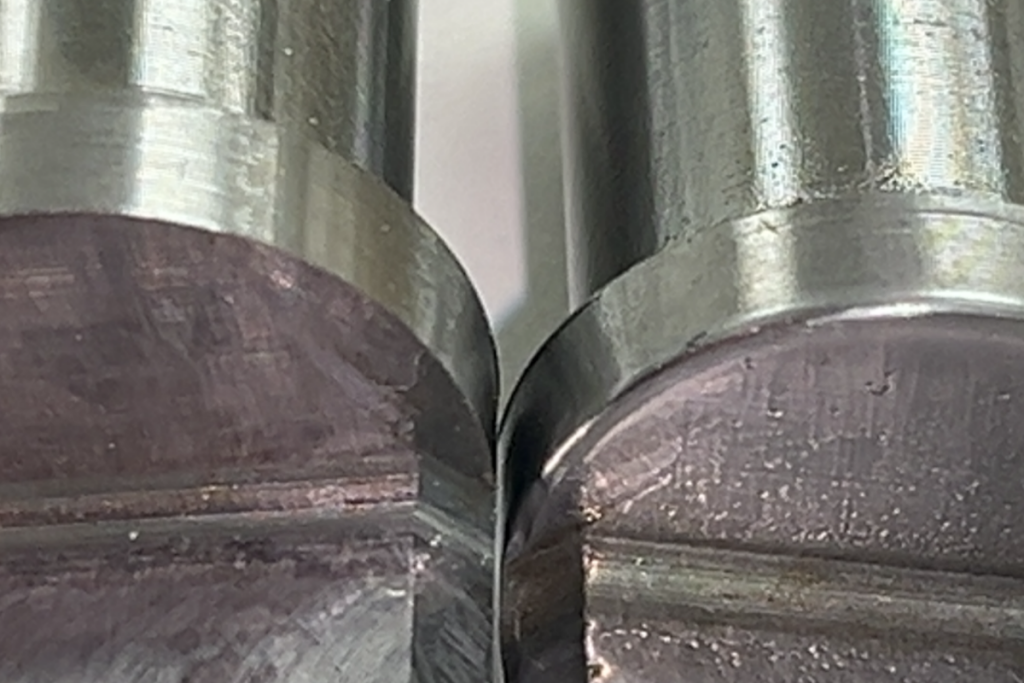

EDGE SHAPING

Create precise edge shapes in your components with a clean, reliable method.

SURFACE PREPARATION

Create reliable bonding surfaces for any metal components.

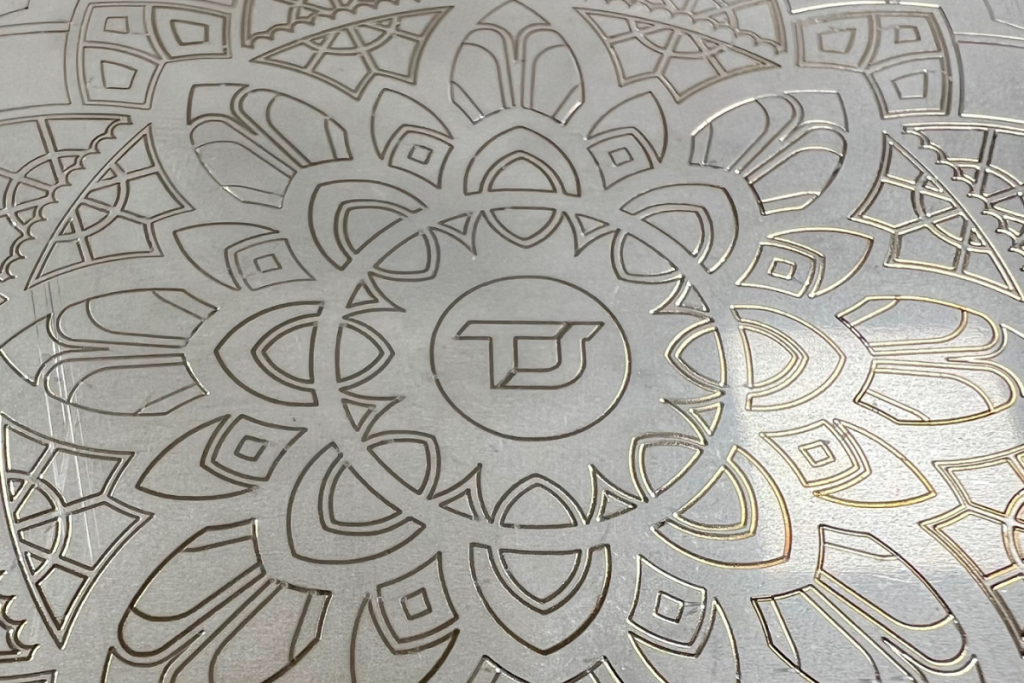

PART MARKING

Create robust QR and similar barcodes on complex and curved surfaces automatically.

Start your project with us today

Have a question or need more information?

Get in touch with us now – we’re here to help!