Oil, Gas and

Power Generation

Precision Surface Processing for Oil, Gas and Power Generation

Engineered for Demanding Oil, Gas and Power Applications

Components in oil, gas, and power generation must perform reliably in some of the harshest operating environments. Our technology delivers precision surface processing that eliminates defects, removes internal burrs, and ensures contaminant-free results.

Even the smallest imperfection can compromise safety, reduce efficiency, or shorten component life. TextureJet’s electrochemical jet machining (ECJM) technology provides a cleaner, more precise alternative to conventional finishing methods. Unlike mechanical processes, it introduces no stress or heat into the material and leaves no abrasive particles or swarf behind.

This makes our technology ideally suited to high-value, low-volume components where quality and precision are essential. ECJM excels in treating complex internal geometries, ensuring burr removal and surface refinement in areas that are otherwise difficult to reach. The process is applied selectively, targeting only the required surfaces without affecting surrounding areas, and delivers contaminant-free results that support the highest standards of safety and reliability.

By enabling manufacturers in oil, gas, and power generation to improve component performance, extend service life, and minimise the risk of in-service failure, TextureJet supports the industry’s demand for safety, efficiency, and long-term durability.

oil, gas & power generation applications

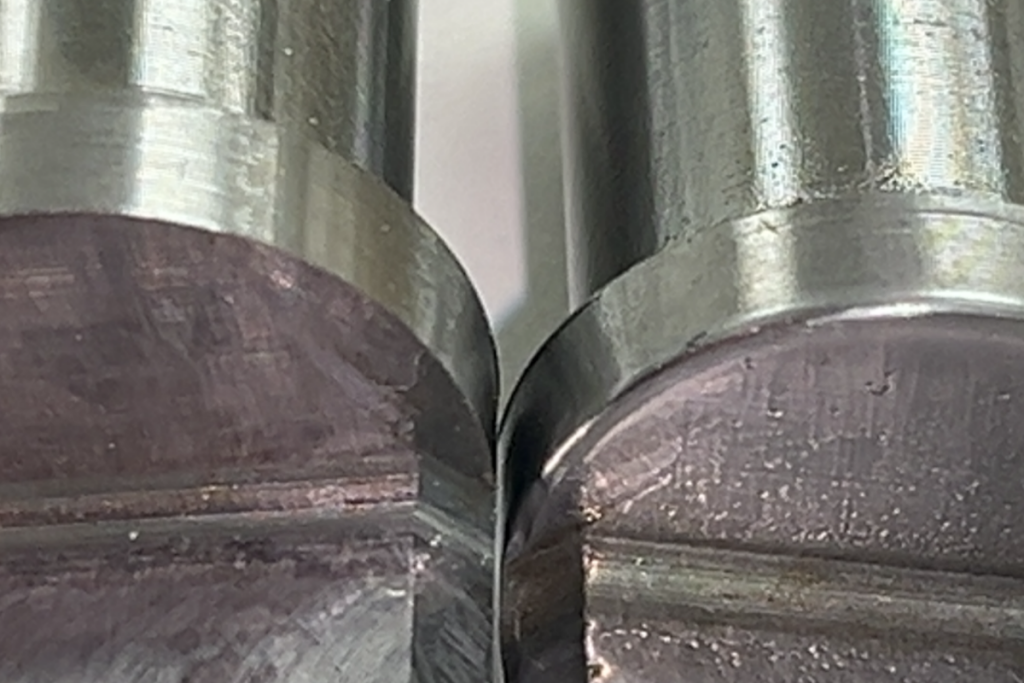

EDGE SHAPING

Create precision edge shapes in your critical parts – deburr and edge break complex geometries, both externally and internally.

SURFACE PREPARATION

Create reliable bonding surfaces for any metal components.

Read more about surface preparation with TextureJet.

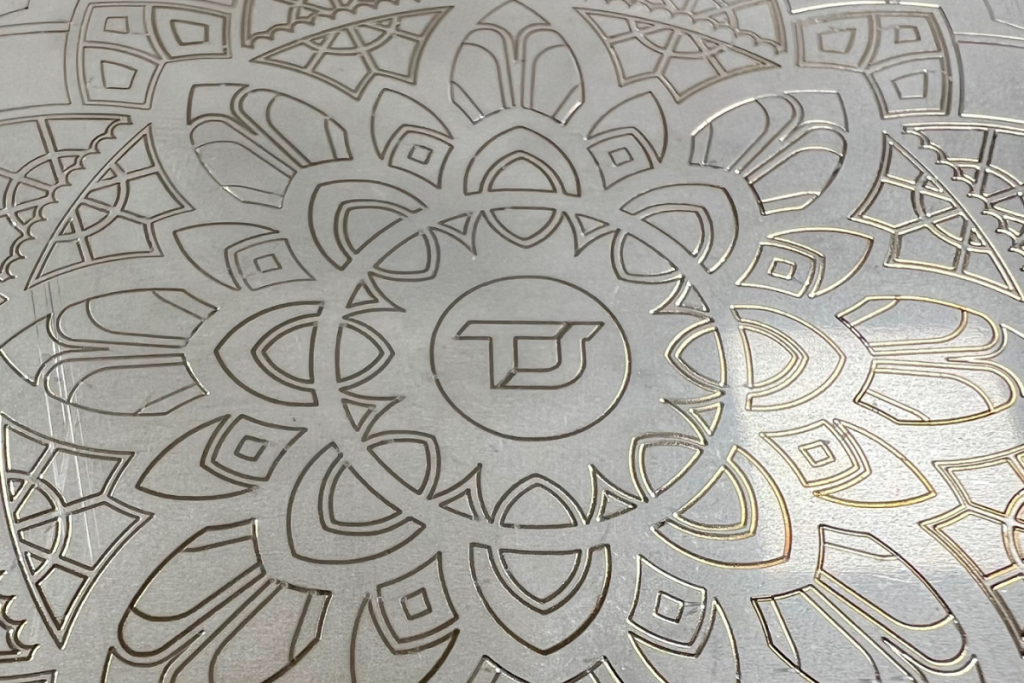

PART MARKING

Create robust QR and similar barcodes on complex and curved surfaces automatically.

Start your project with us today

Have a question or need more information?

Get in touch with us now – we’re here to help!